KNOW-HOW RENOWNED

FOR ITS HIGH PRECISION AND THE MANUFACTURE OF QUALITY MECHANICAL PARTS

LDM IS INTERNATIONALLY RENOWNED FOR ITS HIGH PRECISION AND ITS QUALITY.

With leading-edge technology design and manufacturing systems, our engineers use the very latest computerised programming and industrial production software (CATIA, Mastercam, Missler) and invest 30% of their resources into the research and development of new machining processes for precision parts.

In addition to the production systems used in turning and grinding operations, we also use modern, precise, high-performance and competitive machines, more than 50% of which are made up of palletised, numerically controlled machining systems.

We manufacture very high-precision small parts (micromechanics), starting at 1 mm3, and medium-sized parts measuring up to 800 mm3 for a varied range of machining operations: NC LATHING - NC GRINDING - STRAIGHTENING - HONING - ELECTRO-EROSION - MICROMECHANICS - HIGH-PRECISION TURNING

The quality of our EN/AS/JISQ 9100 and ISO 9001-certified machining, precision, inspection and production of parts reflects our know-how .

The guarantee of the ever-increasing quality of our products has enabled us to implement the most demanding leading-edge programmes and to contribute to the progress of the most advanced techniques, in order to offer a better response to our customers’ needs.

We achieve this by permanently applying our quality policy, meeting the international standards in force (manuals, procedures, internal audits, product audits) and keeping track of every internal and supplier-sourced product.

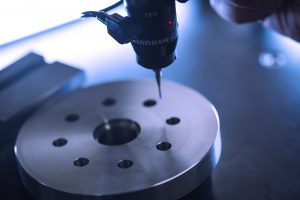

ULTRA-HIGH PERFORMANCE MACHINERY

AND TESTING TOOLS IN THE FOREFRONT OF TECHNOLOGY

MACHINES

- 15 C,Y axis NC lathes

- 5 Nikken indexers

- 15 3-4-5 axis NC machining centres

- 1 laser etching machine

- 1 electro-chemical etching machine

- 1 mechanical etching machine

- 1 AGIE EVOLUTION wire cutter

- 3 AMADA saws

TESTING TOOLS

A workshop managed and organised using the 5S method

- SORT: Only keep what is necessary

- SET IN ORDER: Know where the tools are and keep them in the right place

- SHINE: Keep the workplace clean and detect any anomalies

- STANDARDISE: Use a system of visual indicators

- SUSTAIN: Make sure all the points of the method are applied

Precise testing tools

- 1 ZEISS SURFCOM surface roughness tester

- 2 ZEISS PRISMO-DURAMAX testers

- 1 KEYENCE 3D optical measuring device (we are the first supplier to use this system in France)

A COMPANY THAT CARES ABOUT ITS EMPLOYEES AND THE ENVIRONMENT

EMPLOYEE SAFETY

SOCIAL AND ENVIRONMENTAL RESPONSIBILITY

This is the reason why we have chosen to launch a new CSR plan and to take onboard the ten principles of the Global Compact, which invites companies to adopt, support and apply, within their scope of influence, all the fundamental values in the realms of human rights, working standards and the environment.

Simple actions, which are nevertheless indispensable, such as investing in a cardboard crusher, or in tools to de-oil and change the oil in our machines, or simply the installation of beehives on our site, enable us to contribute to the development of an environmentally-friendly industrial economy.